| Company Details | |

|---|---|

| Company Name | Beep Studio |

| Address | Unit D Juno Way London United Kingdom Map It |

| Name | Peter Ayres |

| Job Title | Director |

| Email hidden; Javascript is required. | |

| Phone | 07876568485 |

| Role of this organisation in the project being entered | Architect / Designer |

| Category |

|

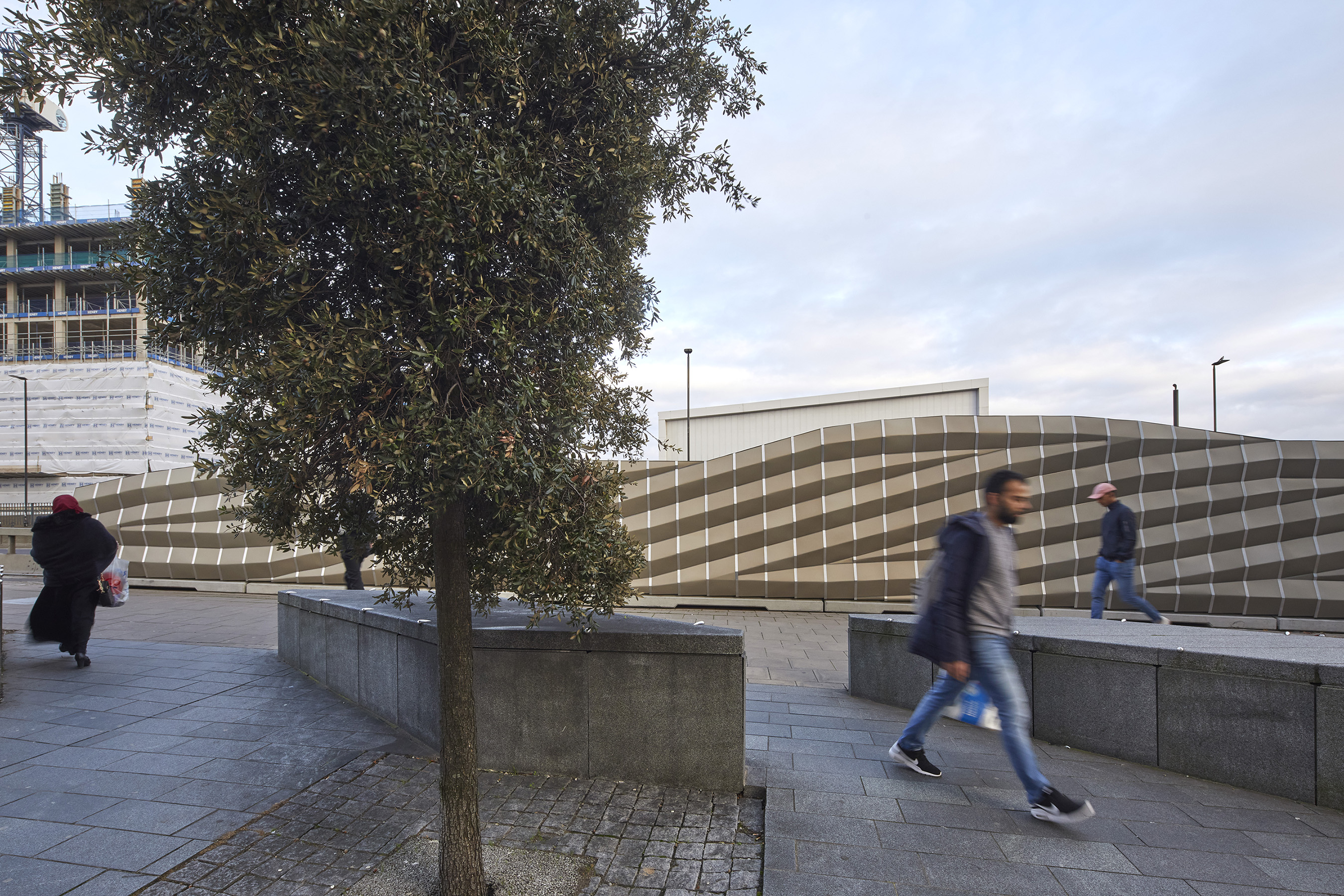

| Project Name (written how it should appear) | A12 Acoustic Barrier |

| Project Address | Jefferson Plaza E3 3NA London United Kingdom Map It |

| Client Name | David Black |

| Designer/Architect Name | Peter Ayres |

| Contractor Name | David Knight |

| Project Description | Both public artwork and acoustic shield, this installation marks the first UK use of an innovative new type of acoustic panels in a construction aimed at reducing people’s experience of noise pollution Each cassette in the assembly is linked together into larger groups, which in turn are mounted to a carefully articulated concrete footing. These footings require no permanent fix to the highway and can be removed through a simple crane lift. DATA Professional Team Suppliers |

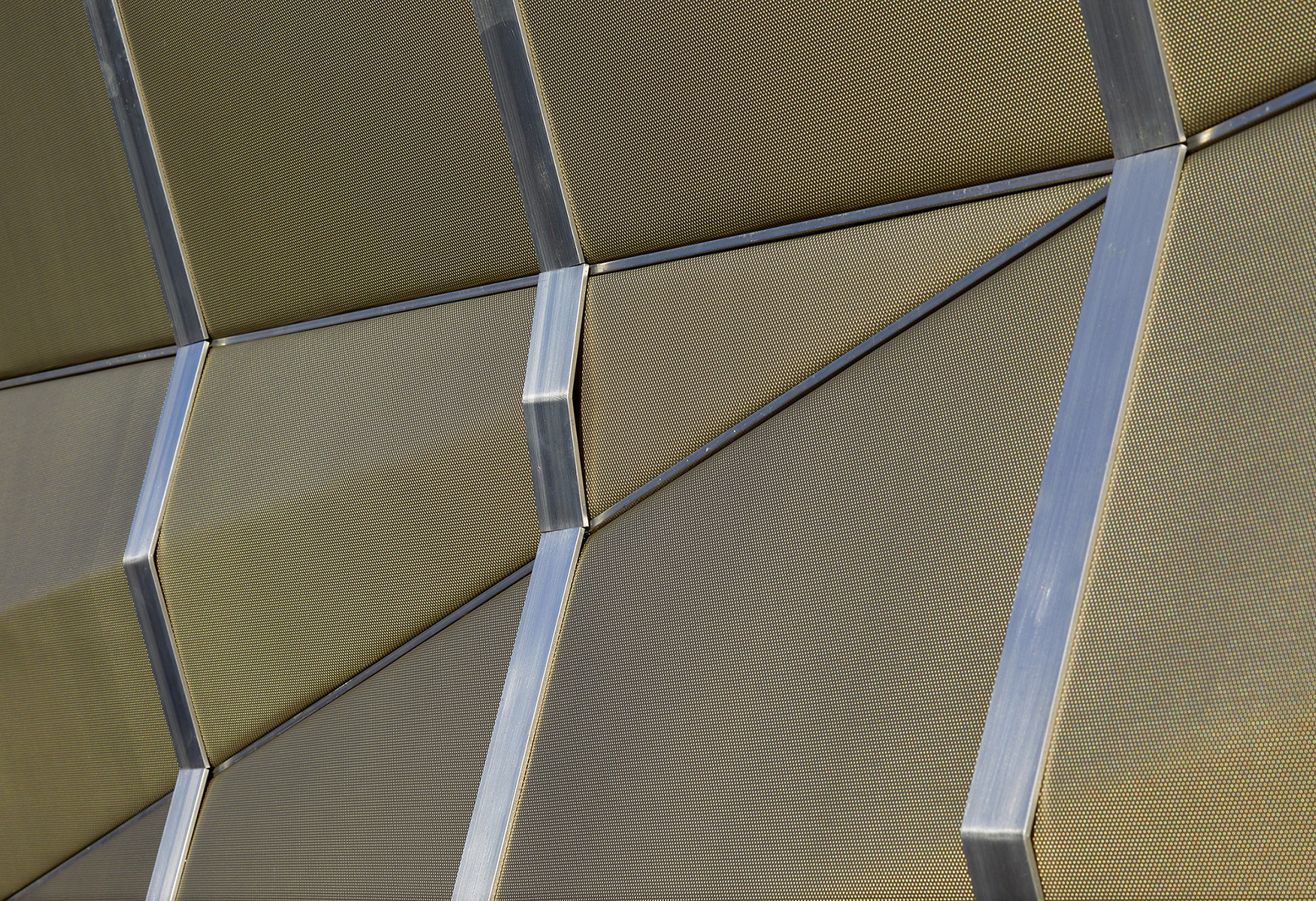

| Materials Used | The Barrier makes innovative use of 'Silk Metal' by Echo Barrier - its first public use in the UK. The challenge of using a delicate material in a harsh public roadside environment led Beep Studio's design. Large sheets of Silk Metal are given strength through folding and splitting into small panes; colour and curved shape provides softness, whilst the faceted design catches light attractively. |

| Sustainability | The acoustic barrier is a test piece intended to improve the roadside environment for pedestrians. The barrier's beneficial impact is being tested by the University of East London, who are measuring qualitative perceptions alongside quantitative effects on noise and traffic pollution. Should the results of these tests prove positive the intent is for the design to be rolled out more widely, improving streets over the capital and beyond. |

| Issues Faced | The surface material was selected by TFL as a prerequisite of the design: |

| Additional Comments | Please see attached video clip for a full description of the project |

| Temporary Structure Entries Only | The structure will be in place for at least one year, starting in November 2020. |

| Video Link | we.tl |

| Supporting Images |